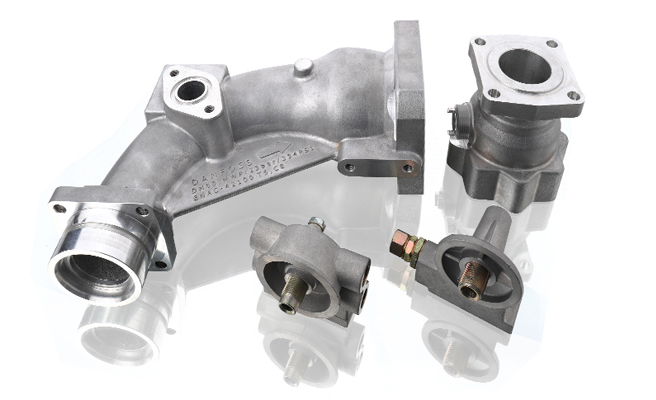

We are ISO 9001、ISO14001、IATF16949、ISO13485 certified. Since 2003, we served our customers with a wide range of die casting

products in aluminum, 0zinc and brass.

Technical capability:

√ 10 years of professional die casting die design and manufacturing experience.

√ 8 person mold design team.

√ 15 person mold processing team.

√ 10 person mold assembly and maintenance team.

√ 31 sets of professional die casting production equipment covering 90-300t.